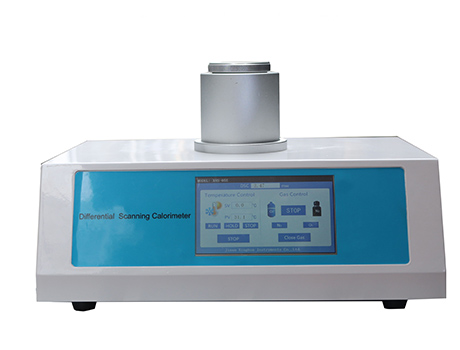

XHinstruments XHS-05 差示扫描量热计 (0 -±500mW)

制造商: XHinstruments Model: XHS-05 - 联系

Call for the best price

Hanoi city: (024) 35.381.269

Danang city: (023) 63.747.711

Bac Ninh city: (0222)730.39.68

HCM city: (028) 38.119.636

Temperature range: Room temperature - 500℃ (-10℃, -20℃, -40℃, -150℃ Selection)

Temperature resolution: 0.01℃

Heating rate: 0.1 -80 C / min arbitrary set

Constant temperature advise: Advise <24 hours

Temperature control mode: Heating, cooling, constant temperature, programmable, temperature continous

DSC range: 0 -±500mW

DSC resolution: 0.01 mW

DSC sensitivity: 0.1 mW

Working power supply: AC110V/220V, 50/60Hz, Single Phrase

Atmosphere control of gas: Nitrogen, oxygen (automatic switching)

Gas flow: 0-200 ml/min

Gas pressure: 0.2 MPa

Crucible: Aluminum crucible, Φ 6.6 * 3 mm

Standard substances: (indium, tin, zinc), the user can correct temperature and heat enthalpy

Data interface: Standard USB interface

Display mode: 24 bit color, 7 inch touch screen display

Output way: Computer and printer

Power: 300W

Fully enclosed bracket structure design prevents articles falling into the furnace body, polluting the furnace body, reducing maintenance rate:

Product Description:

Differential Scanning Calorimeter DSC is designed to determine the inner heat transition relating to temperature and heat flow, it is widely used in the field of polymer development, performance testing & quality control. DSC research and development includes the following field: glass transition temperature, melting point, cold crystallization, crystallization, phase transition, Enthalpy, oxidation induction time (OIT).

Test Standards: ISO/TR10837:1991, ASTM D3895-1998, ASTM E 967, ASTM E 968, ASTM E 793, ASTM D 3895, ASTM D 3417, ASTM D 3418, ISO 11357-6, EN 728 etc.

Product Features:

Widescreen touch structure of industrial level, rich display information, including the set temperature, sample temperature, oxygen flow rate, Nitrogen flow rate, differential thermal signals, all kinds of switch state, the flow rate to zero.

USB communication interface, strong commonality, reliable communication don't interrupt, support the restore the connection.

Furnace structure is compact, arbitrary adjustable heating rate.

Improve the installation process, all adopt mechanical fixed method, completely avoid the furnace internal colloid pollution of the differential thermal signal.

Double temperature probe, make sure the sample temperature measurement high repeatability. Temperature sensor is installed on the furnace wall, PID control the furnace temperature, but due to the temperature of thermal inertia, conduction to the temperature of the sample has a certain deviation, and deviation is different during different season. Therefore, adopt single temperature probe control and measure, no matter differential thermal signals and temperature signals, error is large, there is a temperature sensor at the bottom of sample to be used for measuring sample real temperature, adopt special temperature control accuracy.

Auto switch atmosphere flow, fast and steady.

Data interface: USB interface, professional software.

Parameter standard: With standard materials (indium, tin, lead), User can correct the temperature and heat content according to requirements

Curve scanning: heating scanning and constant temperature scanning

Support notebooks, desktops, Support the Win2000, XP, VISTA, Windows 7/10 operating system

- 质量承诺

- 正品保修

- 送货到家

- 交易简单化