Tapping machine Trade Max

Loose Threads and How to Create Strong, Consistent Threads in Metalworking

Loose threads often appear when the cutting movement is unstable: torque fluctuates, rotation speed does not match the material, or the workpiece vibrates slightly, causing the threads to cut only halfway with shallow pitch. When tightening a bolt, the thread slips easily and cannot hold tension. These issues are common when using hand tools, especially on hardened steel and stainless steel.

Causes of Loose Threads

Threads weaken when the tap does not enter on center, the spindle tilts, or torque is interrupted. Hand tools vibrate easily, so the tap struggles to bite evenly from the first turn. If rotated too fast on steel or stainless steel, the thread surface burns and scratches. If rotated too slowly, chips accumulate and create shallow, uneven pitch.

Another frequent issue is failing to keep the tap vertical at the start. Even a slight tilt causes the thread to drift, making bolts difficult to seat, especially with long bolts or fine pitch.

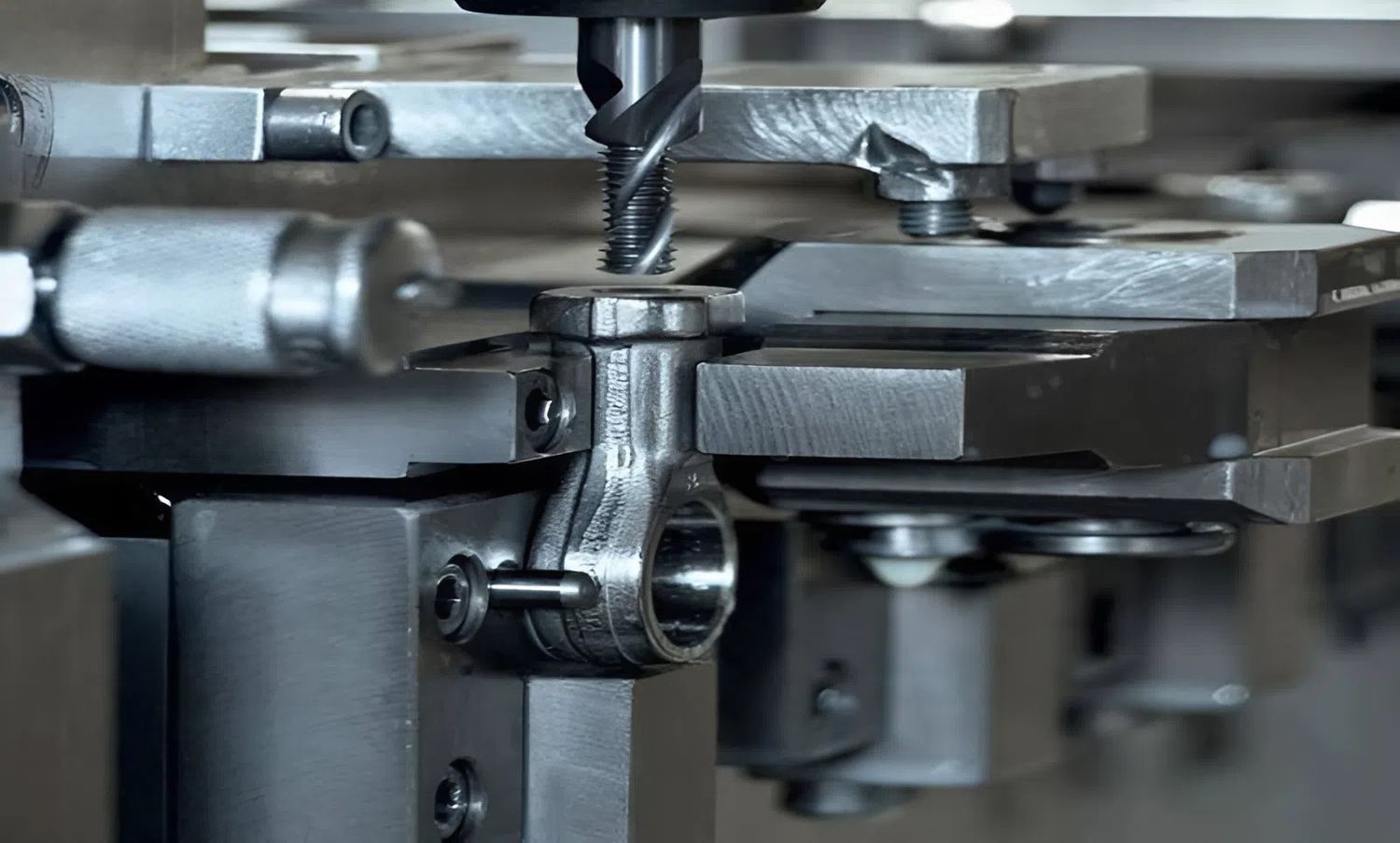

Why Industrial Equipment Creates Strong and Even Threads

Industrial tapping equipment maintains steady rotation speed, consistent torque, and a guided spindle that keeps the tap perpendicular to the work surface. The tap enters the material smoothly from start to finish without vibration, drift, or skipped pitch. Models such as the WDDM Z4120G and KTK LGT 340A have stable guide mechanisms, so when tapping thick steel or stainless steel, threads form evenly with minimal edge damage.

The auto reverse function is another advantage: the tap enters and exits cleanly without tearing the material, and thread depth remains consistent across all turns.

How to Choose the Right Equipment to Prevent Loose Threads

To ensure strong thread engagement, the equipment must deliver sufficient torque for hardened steel, maintain a straight spindle, and adjust speed according to thread diameter. Auto reverse helps the tap cut clean, deep threads without tearing.

For workshops with high production volume, electrically driven or pneumatic systems are the most suitable because they operate quickly, produce fewer errors, maintain stability, and keep thread quality consistent across all parts.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-