Laboratory furnaces help process samples effectively and are a worthy choice today.

As we all see, laboratory furnaces are important equipment, almost indispensable in most laboratories today. So what is a laboratory furnace? What are its uses and what types are they divided into? We will share all of this in the article below.

Contents

What is a laboratory furnace? Definition and function

Laboratory furnaces are specialized equipment in laboratories, used to create very high temperatures, often reaching about 1000°C or more. This equipment helps to process samples, ash materials or chemicals needed for research processes quickly, ensuring accuracy and efficiency. In addition, laboratory furnaces also effectively support chemical reactions that require high temperature conditions.

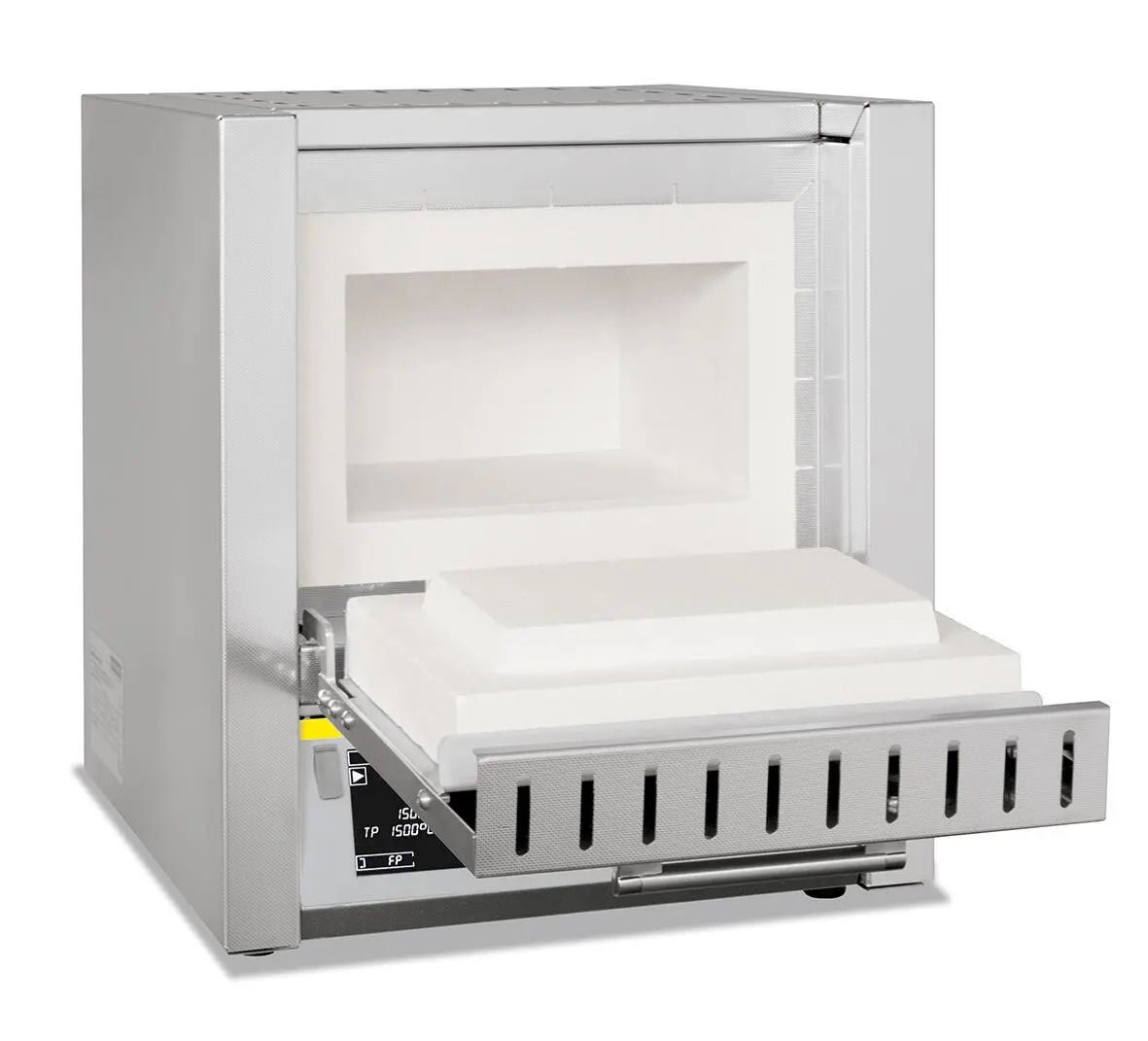

Laboratory furnaces are usually designed with a solid monolithic structure, the shell is made of high-strength steel, fast heating speed, good durability. The device comes with a separate control panel, easy to operate, with an electronic screen that clearly displays the actual temperature and the set temperature.

Outstanding advantages of experimental furnace

Fast heating time, high efficiency, temperature can reach about 1000°C or more.

Heat is evenly distributed, helping to dry or heat samples evenly at all locations.

Equipped with automatic temperature control system, simple operation, easy to use.

Sturdy structure, iron frame with quality insulation layer, minimizing heat loss, safe for users.

With load-bearing wheels, easy to move when needed.

Related article: In what environment are furnaces used?

Classification of experimental furnaces

Laboratory furnaces can be classified based on shape, structure or purpose of use. If considering the design, we can mention popular types such as rectangular chamber furnaces with front opening, tube furnaces or lifting furnaces. In which, tube furnaces are the type of furnace with a seamless structure along the length, not divided into separate compartments. This type of furnace has only one main door used for putting in and taking out samples. The outstanding advantages of tube laboratory furnaces are neatness, space saving and efficient use of heat.

If classified by operating temperature, laboratory furnaces are often selected based on the temperature level that meets the experimental needs:

For ashing and burning work, a temperature of about 500°C to 1000°C is suitable.

For processes that require higher temperatures such as melting and calcification, furnaces that reach nearly 2000°C are often required.

Usually, based on the maximum temperature limit, laboratory furnaces are divided into 3 lines:

- Furnace reaching temperature of 800°C - 1000°C: Using Nickel-Chromium heating wire wrapped around a refractory core. Temperature is controlled by thermocouple combined with automatic voltage controller.

- Furnace reaching temperature of 1100°C - 1200°C: Using heating wire made of special alloy, better heat resistance and arranged close to the sample to optimize heat transfer efficiency.

- Furnace reaching temperature of 1350°C - 1400°C: Using heating rods made of silicon compounds, specifically silicon carbide rods. The sample will be placed in a cylinder and arranged between these heating rods to ensure even heat distribution.

Currently, many large companies in the world have produced high-quality laboratory furnaces. Some popular brands distributed in Vietnam include SH-Scientific, Nabertherm, Hinotek,... with many best-selling models suitable for modern laboratories.

Review of the best laboratory furnaces to own today

One of the highly rated and worth-investing laboratory furnace models at the moment is the 1100°C 15-liter tilt-up furnace model LT15/11 from Nabertherm. This is an outstanding device with high precision, optimized design for users, very suitable for laboratories that need to analyze samples, research chemicals and perform reactions that require high temperatures.

Basic technical parameters of the Nabertherm furnace:

Maximum temperature: 1100°C

Cylinder volume: 15 liters

Controller: B180 with clear LCD screen

Function: Temperature - time setting by cycle, automatic protection when overheating, overvoltage or overcurrent occurs

Power: 3.6 kW

Weight: about 55 kg

Maximum heating time: 99 minutes

In addition, the device also integrates the ability to adjust the air intake right on the furnace door and has an additional exhaust port at the back, helping to minimize noise during operation.

In addition to the above model, we also provide many other laboratory furnace options to meet diverse needs:

1100°C furnace, 15 liter swing-down door L15/11 Nabertherm

1100°C furnace, 3 liter swing-down door L3/11 Nabertherm

1100°C furnace, 9 liter swing-down door L9/11 Nabertherm

See product details at: NABERTHERM LT 15/11 Furnace (1100°C, 15L)

All Laboratory Furnace equipment see at: EMIN Laboratory Furnace Equipment

Conclude:

EMIN is a leading prestigious unit specializing in distributing 100% genuine laboratory equipment, committed to quality and comprehensive after-sales, maintenance and repair policies. Any consulting needs or questions of you will be supported by our team 24/7. Please contact us directly to receive the most detailed information.